Written by Hasan Galib

Illustrated by Tammy Lee

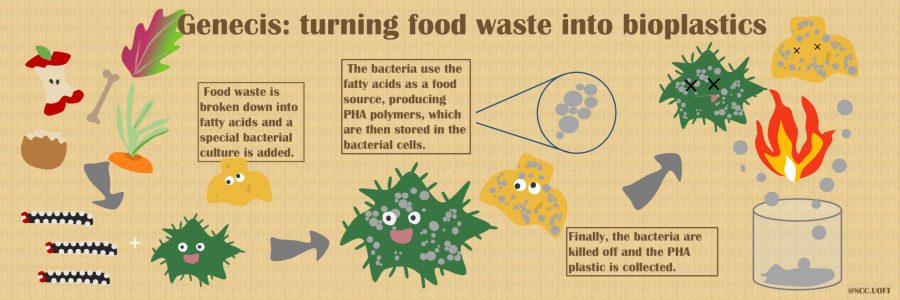

Genecis, a start-up at the University of Toronto Scarborough, led by founder and CEO Luna Yu is using recent advances in microbiology to make bio-plastics. They are harnessing the power of a special kind of bacteria to produce biodegradable polymers called polyhydroxyalkanoates (PHA) from food wastes. The conversion process is quite simple: the food waste is broken down into fatty acids and a special bacterial culture is added. The bacteria use the fatty acids as a food source, producing PHA polymers, which are then stored in the bacterial cells. Finally, the bacteria are killed off and the PHA plastic is collected.

Many attempts have been made to create biodegradable plastics, but so far it has been hard to integrate them into our current waste management systems. In contrast, the chemical structure of PHA allows these bio-plastics to be easily modelled and remodelled without posing any problems to the recycling process. Furthermore, PHA plastic products produced by Genecis are showing great promise, as they can be used to produce a wide range of multiuse products from toys to surgical sutures. Even better, these products degrade within one year in the environment and less than 10 years in water!

It is hard not to appreciate the environmental impact of Genecis’ innovations. Currently, $1 trillion worth of food is wasted globally every year, with $31 billion in Canada alone (to put this into perspective, that’s 873 pounds of food wasted per person every year!). Since synthetic plastic waste management is another major problem we are currently facing, it is no surprise Genecis has garnered so much support, winning more than $330,000 in prize money from start-up competitions! Yu and her team of scientists, most of whom are U of T graduates like Yu herself, are now partnering up with industrial professionals to ramp-up their production, and in the future, expand into the production of other products to create the highest value from organic waste.