Written by Angelico Obille

Illustrated by Janell Lin

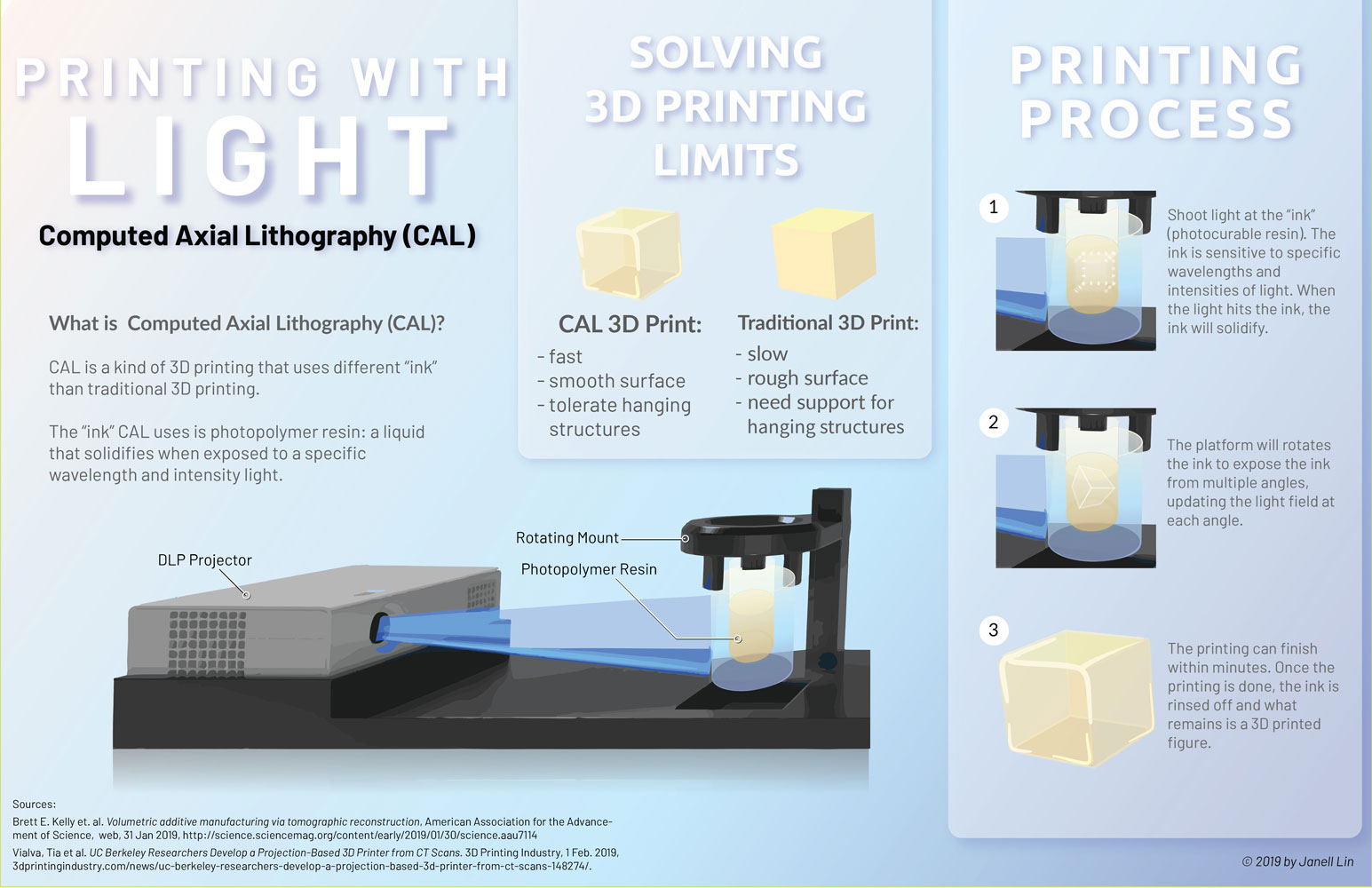

The advancements of 3D printing in the last few decades have brought our society closer to the futuristic world ever fantasized by many of us science enthusiasts. Among its many applications, 3D printing has proven to be very useful for medicine. Recently, a team from UC Berkley has created a new method of 3D printing called Computed Axial Lithography (CAL) to improve the method of ink deposition in the printing process, designed for medical use.

With 3D printing, surgeons can take patients scans and create personalized organ models with correct dimensions and features to help them plan their operations. Permanent implants for dentistry or orthopedics can be made with high accuracy in real-time. Bioactive and biodegradable scaffolds can be crafted and implanted to promote a specific response, such as tissue repair and healing. Some researchers are even exploring the creation of tissues and entire organs.

The traditional method of 3D printing is “additive manufacturing”, which involves layer-by-layer deposition of ink, building the figure bottom-up from a platform. You can imagine this poses some limitations: it’s a slow process, the surface isn’t smooth, and it is difficult to create figures with multiple components.

Enter Computed Axial Lithography (CAL): the newest method of 3D printing, using a chemical reaction (called photopolymerization). The ink used here is sensitive to specific wavelengths and intensities of light. When a photon of a specific wavelength and intensity hits the ink, the ink solidifies.

Amazingly, the team was able to program a projector to shine light with incredible precision on printed structures which solidified the ink in a matter of minutes! Once the printing is done, the ink gets rinsed off and what remains is a 3D printed figure that seemingly comes out of nowhere!

A lot of work still needs to be done to fine-tune the process and widen its applications, but one thing is for sure: this new technology shows there truly are no limits in science – any fantasy can become a reality!

Sources:

- Yan, Q., Dong, H., Su, J., Han, J., Song, B., Wei, Q., Shi, Y. “A Review of 3D Printing Technology for Medical Applications”. Engineering. 2018. DOI: 10.1016/j.eng.2018.07.021

- Kelly, B.E., Bhattacharya, I., Heidari, H., Shusteff, M., Spadaccini, C.M., Taylor, H.K. “Volumetric Additive Manufacturing via Tomographic Reconstruction”. Science. 2019. DOI: 10.1126/science.aau7114